OptiEdger

-volume optimizer

The OptiEdger edging volume optimization

OptiEdger is an edging optimization system that maximizes the volume of sawn flitches. Currently, volume optimization is the most commonly used edging optimization method in the sawmill industry.

OptiEdger measures the wane profile of board pieces using triangulation. The measurement technology is based on line lasers and a matrix camera that takes 1,000 images per second. The system optimizes the volume of the pieces using the wane data.

The flitch profile to be edged can be measured on one face or both faces of the flitch at the same time, which means that there is no need to turn the flitch being processed. If necessary, three measuring units can be used on each side of the board, thus reducing the distance between the measuring units and the edger.

Office electronics is no match for this line of work

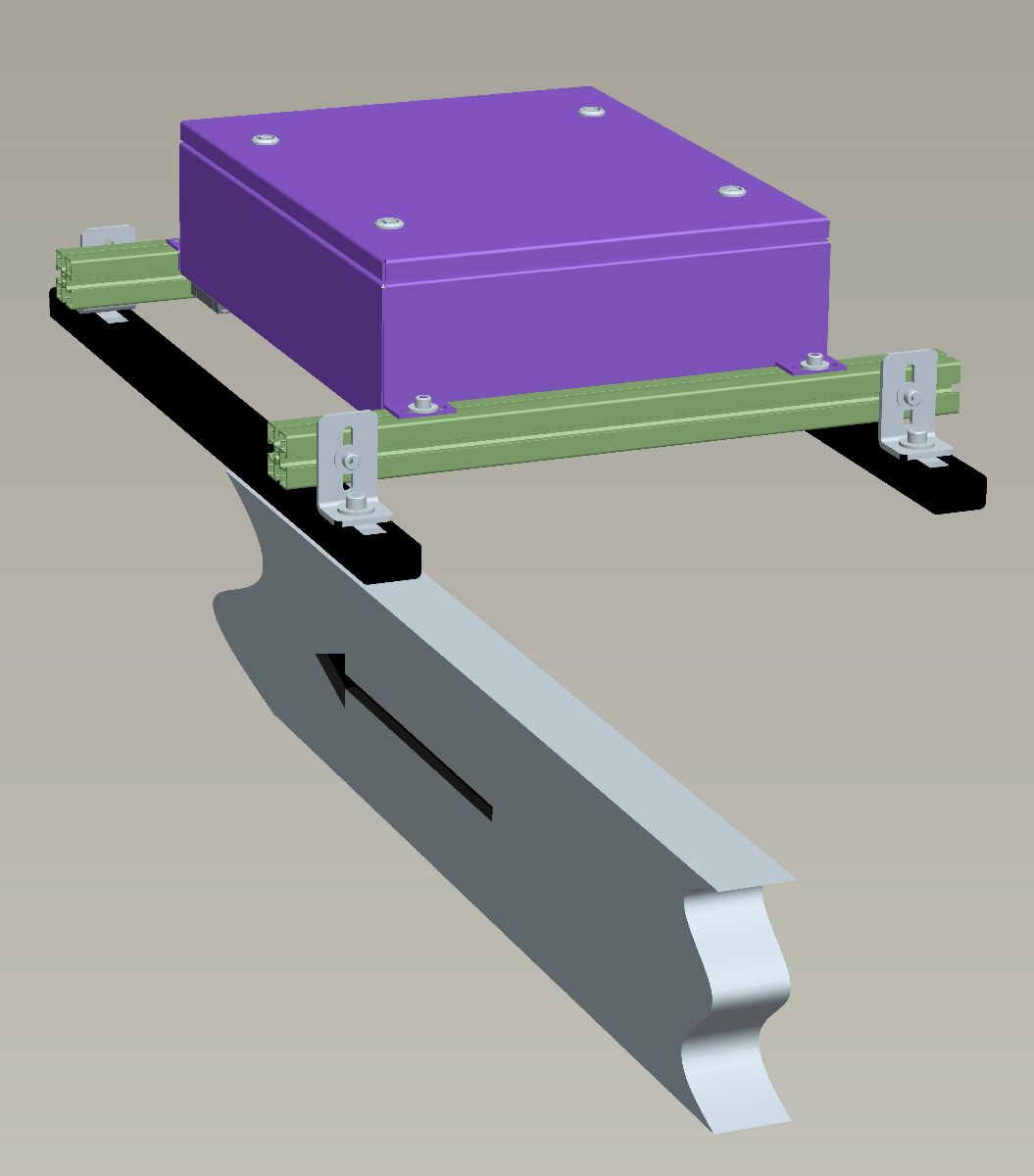

The system electronics was designed for industrial conditions and the equipment processing power was dimensioned for machine vision applications that require massive computing power. This ensures the equipment’s reliability and the measurement accuracy, which cannot be achieved by computers designed for office purposes.

The user interface complies with the specific needs of wood processing, providing a clear view of the production in progress. The user sees the measurement results of all pieces being processed and also the optimization results in a clear graphic form.